In this comprehensive guide, we will define Lost Time Injury, discuss its implications, emphasize the importance of LTI prevention, and highlight best practices for promoting a culture of safety. Whether you are an HSE professional seeking detailed insights or a reader interested in workplace well-being, this guide will equip you with essential knowledge.

Definition of Lost Time Injury (LTI)

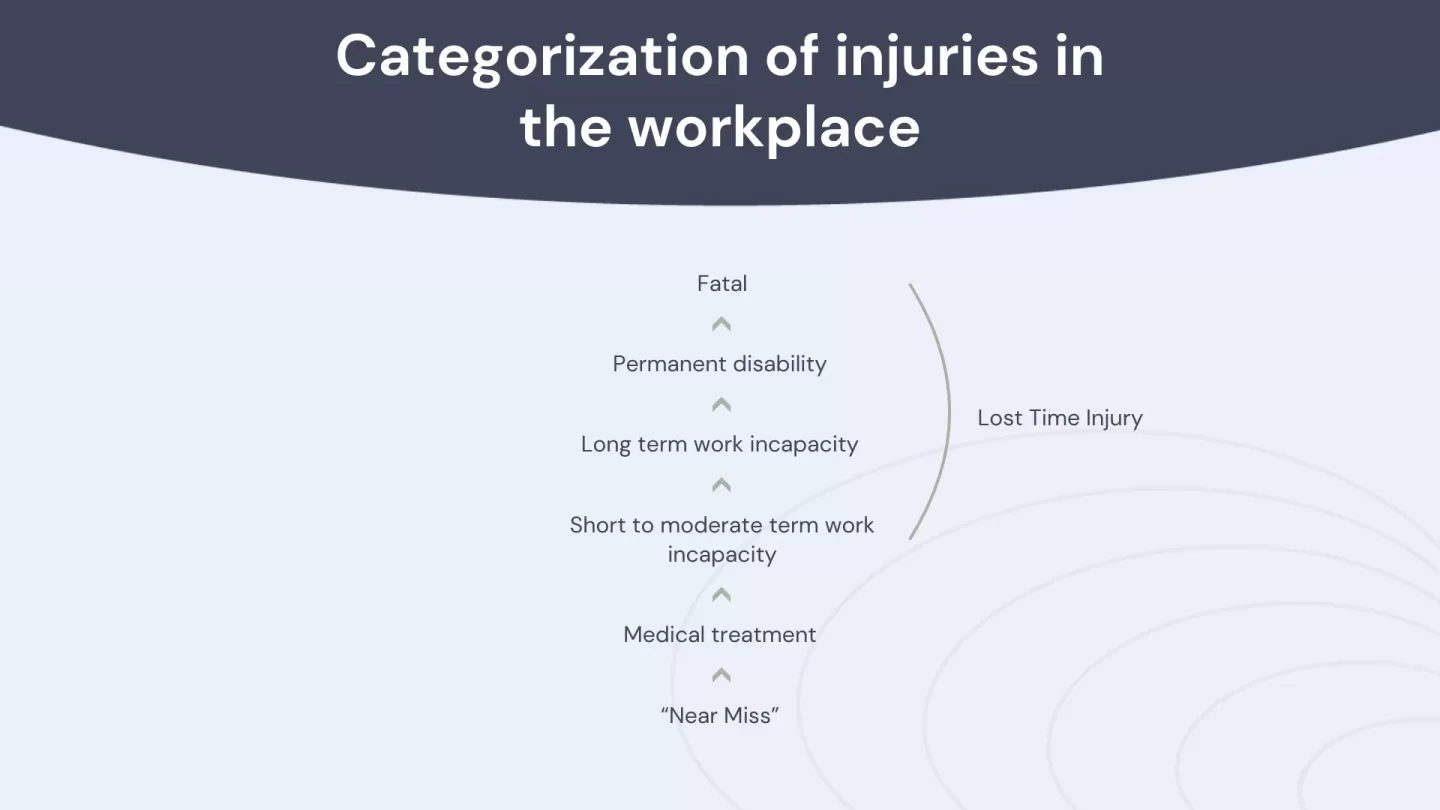

Lost Time Injury (LTI) refers to a workplace injury that results in an employee being unable to perform their regular duties for a specified period, typically one day or shift. LTIs are often used as a key metric to measure the safety performance of an organization, reflecting the number of lost workdays due to work-related injuries.

Understanding LTI Severity and Frequency Rates

LTI severity and frequency rates are commonly used to assess the impact of LTIs within an organization. The severity rate indicates the average number of days lost per LTI incident, providing insights into the seriousness of the injuries. The frequency rate, on the other hand, represents the number of LTIs per a specific number of hours worked, indicating the frequency of incidents within a given timeframe.

Picture 1: Categorization of injuries in the workplace. Not all of them are considered in the calculation of LTI.

Importance of Lost Time Injury Prevention

Preventing Lost Time Injury is of paramount importance for several reasons. Firstly, it protects the well-being and safety of employees, ensuring they can work in a secure environment. Secondly, LTI prevention minimizes productivity losses, reduces absenteeism, and avoids financial costs associated with workplace injuries. Moreover, a proactive approach to LTI prevention enhances employee morale, fosters a positive work culture, and contributes to the overall reputation and success of the organization.

Best Practices for Preventing LTIs:

To effectively prevent LTIs, organizations should implement the following best practices:

Leadership Commitment

Demonstrate visible commitment from leadership, promoting a culture of safety and accountability throughout the organization.

Safety Policies and Procedures

Establish clear safety policies and procedures, communicating them effectively to all employees and contractors.

Risk Assessment and Hazard Identification

Conduct regular risk assessments to identify workplace hazards, analyze potential risks, and implement preventive measures.

Training and Education

Provide comprehensive safety training to all employees, ensuring they have the necessary knowledge and skills to identify and mitigate risks.

Incident Reporting and Investigation

Implement a robust incident reporting system, encouraging employees to report near-misses and incidents promptly. Conduct thorough investigations to identify root causes and implement corrective actions.

Continuous Improvement

Foster a culture of continuous improvement by regularly reviewing safety performance, analyzing trends, and implementing corrective measures to prevent future LTIs.

Conclusion:

In conclusion, Low Time Injury (LTI) prevention is crucial for creating a safe and healthy work environment. By understanding LTIs, their severity and frequency rates, and implementing best practices for prevention, organizations can protect their employees, enhance productivity, and maintain a positive work culture.

Frequently asked questions

What is the significance of Low Time Injury (LTI) in measuring workplace safety?

LTI is a crucial metric for measuring workplace safety as it reflects the number of lost workdays due to work-related injuries. By tracking LTIs, organizations can assess the effectiveness of their safety programs, identify areas of improvement, and monitor the impact of safety initiatives.

By conducting thorough risk assessments to identify workplace hazards and implement appropriate controls. Providing comprehensive safety training to employees, ensuring they are equipped with the knowledge and skills to recognize and mitigate risks.

How can employees contribute to preventing Low Time Injuries (LTIs)?

Following safety protocols and procedures, including wearing appropriate personal protective equipment (PPE). Reporting hazards, near-misses, and potential risks to supervisors or the designated safety officer.