If you’re considering a career as a Welding Engineer, this guide provides essential insights to kick-start your journey in the field.

Why work as a Welding Engineer

Working as a Welding Engineer offers a unique combination of hands-on technical work and innovative problem-solving opportunities. In this role, you will be at the forefront of building and maintaining the essential structures and machinery that power our world, from towering skyscrapers to vital transportation networks. This position also helps develop new materials and ensure the safety and efficiency of engineering projects.

What does a Welding Engineer do?

Welding engineers are instrumental in improving the efficiency and profitability of welding projects in a variety of industries. Their core responsibilities include optimizing welding processes and strategically planning improvements to ensure quality results. Welding engineers combine their knowledge of materials science, engineering principles, and project management to ensure that all welded structures are safe, durable, and built to the highest quality standards.

Welding Engineer salary and benefits

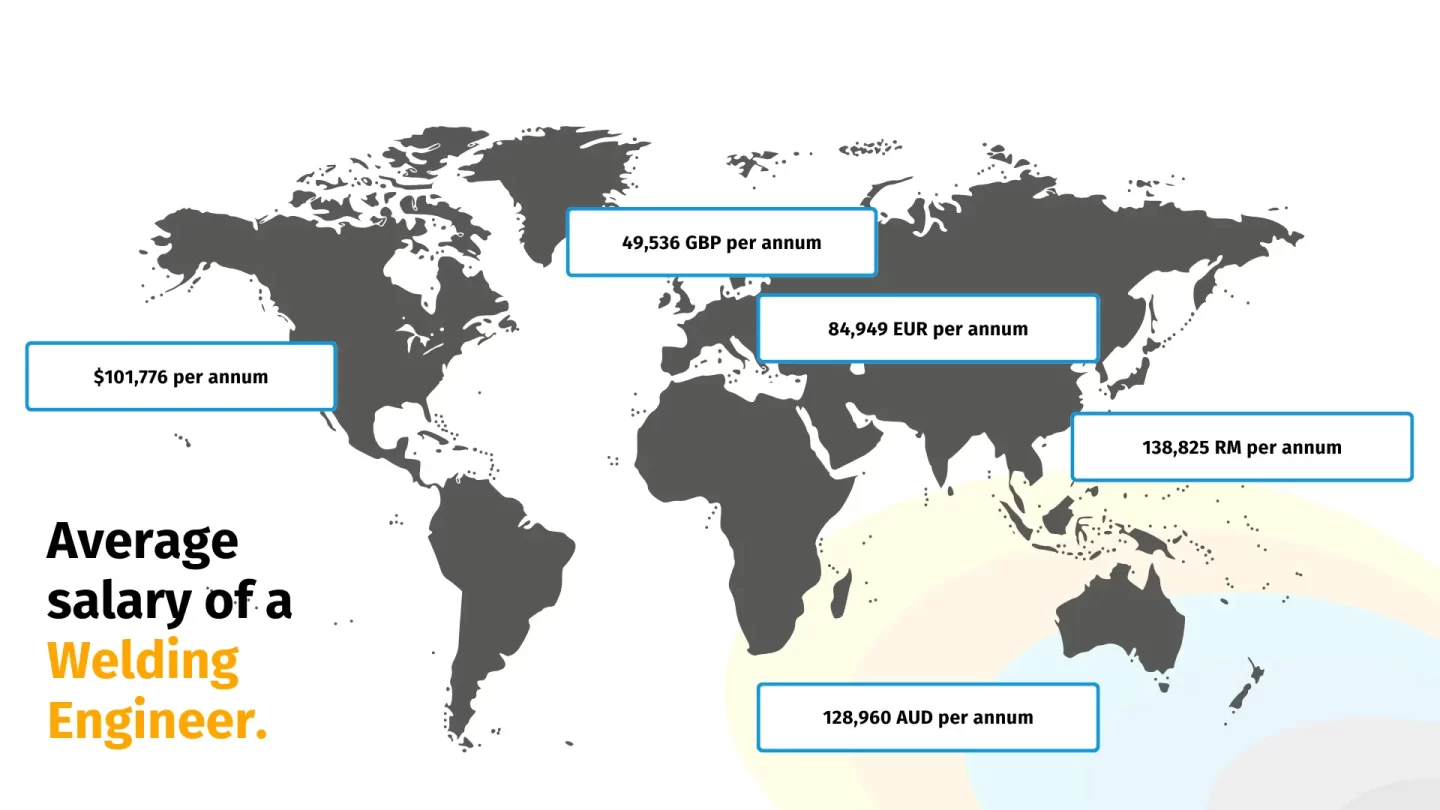

As shown by data collected in August 2024.

The salary for Welding Engineers varies globally, influenced by industry demand, experience, and geographical location. In the United States, the average Welding Engineer salary is $101,776 as of August, 2024, but the salary range typically falls between $93,210 and $111,545. In countries like Germany, where the manufacturing and engineering sectors is booming, salaries are competitive and can be close to U.S. levels. The average salary range for a Welding Engineer is between €58,677 and €103,512.

In the UK , Welding Engineers can expect to earn between £47,840 and £50,029 annually. In regions like the Middle East, where the oil and gas industry is dominant, The average salary range for a Welding Engineer in United Arabia Emirates is between AED 215,232 and AED 379,692.

Normally welding engineers benefit from a compensation package beyond their salary. This includes health insurance, retirement plans, paid vacation, and sometimes bonuses or profit sharing. For positions that require travel or relocation, companies may offer housing allowances and travel reimbursement. In addition, many employers support career development by funding continuing education and professional training, enhancing the long-term career prospects and expertise of welding engineers.

Responsibilities of a Welding Engineer

Welding engineers are responsible for designing welding schemes, choosing appropriate materials and methods, and ensuring the welds meet structural requirements. Here’s a briefing overview of responsibilities:

Project Analysis and Coordination

They assess engineering designs, define needs, and manage project execution, including supervising external lab tests.

Inspection and Compliance

You will conduct inspections, report on results, and monitor compliance with industry codes and design specifications.

Procedure Oversight and Innovation

They evaluate and improve welding procedures, ensuring they meet design requirements and innovate to enhance processes.

Technical Support and Consultancy

They support engineering teams in fabricating equipment to client and code specifications and provide project guidance.

Quality Assurance and Material Auditing

you will also audit suppliers for quality materials and develop testing procedures to uphold standards.

Troubleshooting and Repairs

They analyze project failures, troubleshoot delays or quality issues, and recommend repairs to achieve desired outcomes.

Welding engineer skills and requirements

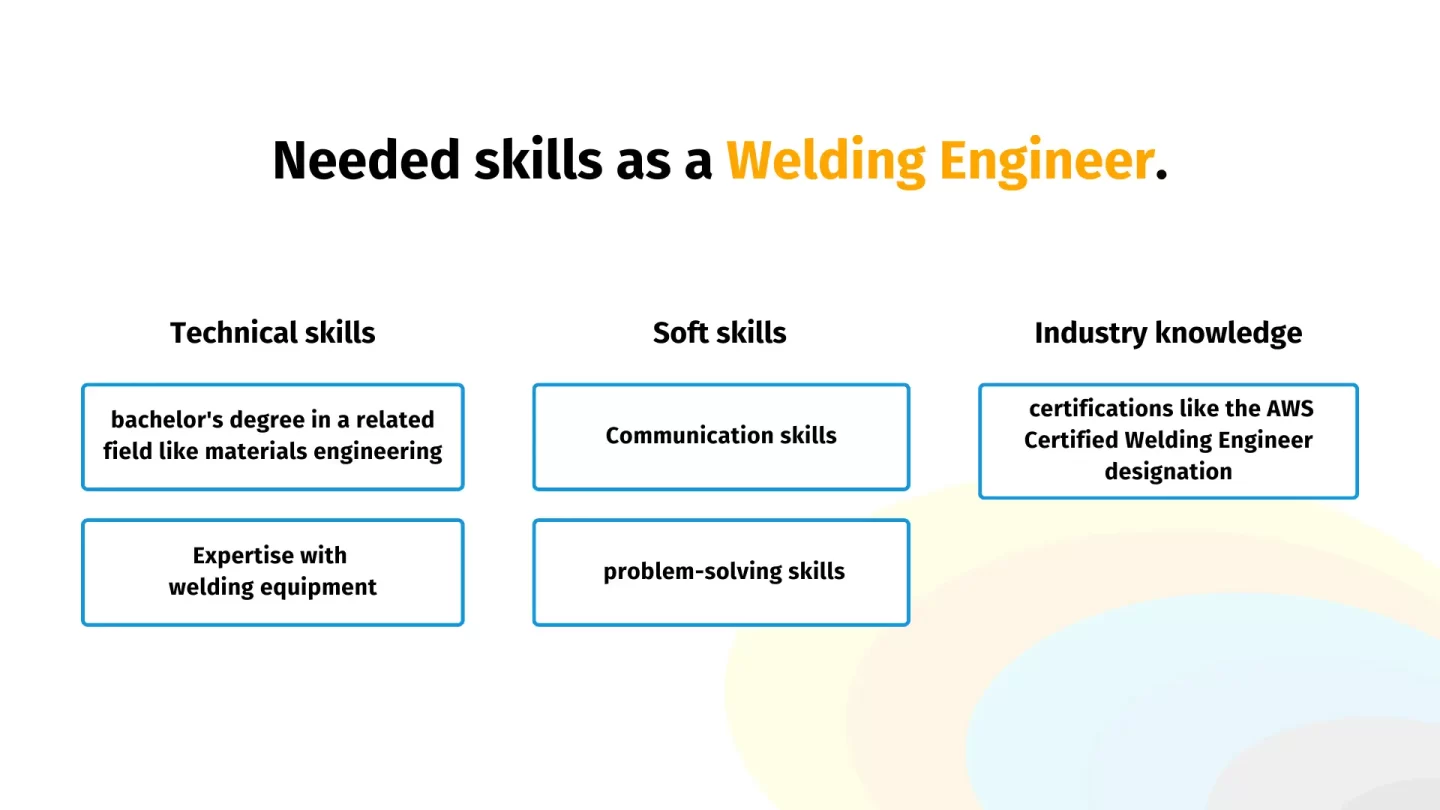

You’ll need a strong foundation in several key skills to meet the diverse demands of the role. First, your ability to organize, pay attention to detail, and think analytically will be fundamental. These skills are critical for overseeing complex projects. Excellent communication skills are also essential to ensure clear coordination with teams and stakeholders, and to manage project documentation and client interactions.

As you progress, your role will require problem-solving skills and a deep understanding of technology to solve problems and implement innovative solutions. Physical abilities are also important due to the manual aspects of welding, which require good hand-eye coordination and dexterity. Over time, developing these skills will allow you to take on more complex projects and lead innovation in your field.

Locations of Welding Engineer jobs

Welding Engineer jobs are widely available across key industrial and manufacturing hubs globally. In the United States, states like Texas, California, and Ohio are hotspots due to their extensive manufacturing sectors and infrastructure projects.

Internationally, countries such as Germany, Japan, and those in the Middle East, particularly with active oil and gas industries, offer significant opportunities. This global presence allows Welding Engineers to find jobs in regions that suit their career ambitions, including options for international projects or relocation.

Career progression and growth opportunities

The career usually start with entry-level jobs. They gain experience and skills to move up to more responsible roles. Specializing is important for career growth. Welding engineers can focus on specific industries like aerospace, automotive, construction, or marine. Each industry requires different skills and knowledge. A degree and specialised certification can make an engineer more attractive to employers.

For those interested in leadership, there are opportunities to move into managerial positions where they can shape project direction and innovation or even step into executive roles within engineering firms.

Moreover, experienced Welding Engineers can also transition into consultancy roles, offering expert advice on complex projects or regulatory compliance, further diversifying their career opportunities and growth potential.

There are many job opportunities in this field because welding is used in many industries. Experienced welding engineers can lead large projects, oversee research, or move into executive positions. Also, new materials and welding tech keep learning and specialization opportunities open, so careers always develop.

Work environment and culture

Welding engineers typically experience work environments that go beyond the traditional office. Their work often takes place in a variety of settings, including manufacturing plants, testing laboratories, and active construction sites.

Due to the nature of their projects, you need to travel to oversee operations, meet with clients, and ensure project requirements are followed. This job requires adaptability and a willingness to take on challenges on the road.

Welding engineers work in teams, innovating and striving for quality and safety. You can learn from each other and from their field. They are precise and accountable, which is important for their work. This makes their role important and rewarding, as they contribute to modern infrastructure.

How to Become a Welding Engineer

To become a welding engineer, a bachelor’s degree in a related field like materials engineering is preferred. Internships are important for gaining experience and improving job prospects. After graduation, consider advancing your education with a master’s degree in specific industries such as aerospace or construction.

Starting your career in an entry-level position will help you gain experience in different environments include manufacturing plants, construction sites, off-shore drilling companies and pipelines. Most states require welding engineers to have a license. You can get one after several years of experience and passing a test. You can also earn certifications like the AWS Certified Welding Engineer designation can validate your expertise and dedication to the field.

Benefits of working as a Welding Engineer

A career as a welding engineer offers many benefits, including entry through various certification paths that don’t always require formal education. The job is secure because there is a need for welders in many industries, including construction and architecture. It also offers flexibility, allowing you to take on extra jobs or even start your own business. There are also many different jobs in welding. You can often get extra benefits like housing and healthcare. This helps you to learn and develop your skills.

Drawbacks of working as a Welding Engineer

This role works in a challenging environment with high heat and heavy machinery. Safety is a top priority. Working outside can be hard, especially in bad weather. Operations usually stop during severe conditions. The job often requires long hours, including overtime and travel. This can be tiring, but it can also be very profitable. The job involves working in tight spaces, which can be strenuous. With experience, you can develop more efficient methods and become more comfortable with the equipment.

Current vacancies

For current Welding Engineer vacancies, WTS Energy offers a gateway to advancing your career in the energy sector. With a wide range of opportunities around the world, you can get involved in projects that are at the forefront of the energy transition. Whether your interest lies in Oil and Gas, Renewables, or the nuclear industry, our dedicated recruiters are committed to addressing your career aspirations and helping you find the right job in the right place.