A vortex generator actively creates controlled vortices to improve aerodynamic performance in fluid dynamics. Professionals frequently apply it to wind turbine blades or aircraft wings.

They play a crucial role in enhancing aerodynamic performance by manipulating airflow patterns. These devices are commonly used in applications such as wind turbine blades and aircraft wings to control and optimize airflow, improving efficiency and stability.

What is a Vortex Generator?

A vortex generator is a specialized device used to create controlled swirling motions in fluid flow. By strategically placing these devices on surfaces exposed to airflow, such as wing surfaces or turbine blades, engineers can influence airflow patterns to achieve desired aerodynamic effects.

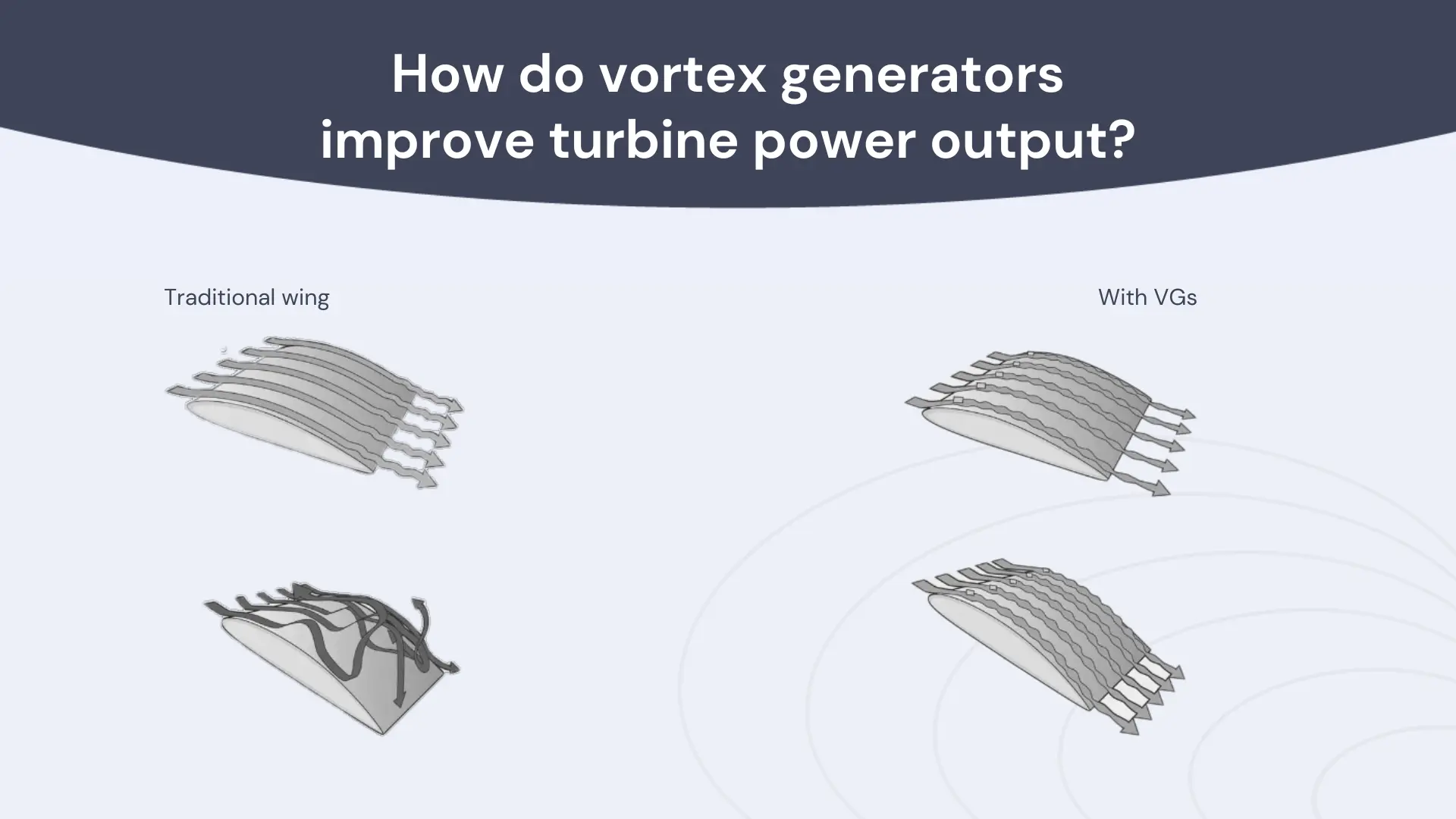

Compared with traditional wing, vortex generators can reduce airflow separation to improve turbine power output. Source.

Key Features of Vortex Generators

They typically possess the following characteristics:

Aerodynamic Shape

They have aerodynamic profiles that are carefully crafted to efficiently produce specific types of vortices.

Mounting Structure

These devices attach securely to surfaces using various methods, minimizing aerodynamic interference.

Size and Placement

Engineers carefully determine the size and placement of vortex generators based on intended aerodynamic goals and flow conditions.

Applications of Vortex Generators

There are several applications in various industries and technologies, including:

Aviation

Aircraft wings commonly use vortex generators to boost lift, cut down on drag, and increase stability, particularly during low-speed flight or stall conditions.

Wind Energy

In wind turbine technology, engineers use vortex generators on blade surfaces to optimize aerodynamic performance, boost energy capture, and decrease turbulence-induced fatigue.

Automotive Engineering

Vehicles often feature vortex generators on surfaces such as car roofs or rear spoilers to boost aerodynamic efficiency, enhance stability, and conserve fuel.

Benefits

The utilization offers several benefits, including:

Enhanced Aerodynamic Performance

They effectively manipulate airflow to achieve desired aerodynamic effects, such as improved lift, reduced drag, and increased energy capture.

Increased Efficiency

By optimizing airflow patterns, they contribute to the overall efficiency of fluid dynamic systems, leading to improved performance and energy utilization.

Improved Stability

The controlled vortices help enhance stability and control, particularly in challenging operating conditions or turbulent environments.

Conclusion

In conclusion, vortex generators are essential devices in fluid dynamics that control and optimize airflow patterns to enhance aerodynamic performance. They play a pivotal role in improving efficiency, stability, and energy utilization across various industries and technologies, whether applied to aircraft wings, wind turbine blades, or automotive surfaces.

Frequently asked questions

How do vortex generators work?

They strategically placed on surfaces exposed to airflow induce controlled vortices in fluid flow. These devices create specific types of vortices that influence airflow patterns to achieve desired aerodynamic effects, such as improved lift, reduced drag, and enhanced stability.

What are the key features of vortex generators?

They typically feature aerodynamic shapes designed to efficiently produce specific types of vortices. They attach securely to surfaces using different methods to minimize aerodynamic disruption. Engineers carefully select their size and placement based on specific aerodynamic goals and flow conditions

Where are the applications of vortex generators?

They have a wide range of applications in industries such as aviation, wind energy, and automotive engineering. Aircraft wings often use them to improve lift, reduce drag, and enhance stability.